|

Production facilities of DITTON Driving Chain factory insures the whole production cycle of driving roller chains:

|

Design and development

|

- The production process starts with the development of the technical drawings, as well as of appliances and equipment.

- Steel selection of the required quality, e.g., pins, bushes, rollers are manufactured from alloy steel, whereas plates from high-carbon alloy steel.

|

|

Manufacturing and maintenance

|

- Manufacturing of plates on high speed stamping presses

- Production of round parts (bushings, rollers) on cold heading machines

- Processing of parts on program-controlled grinding, turning and milling machines to show high surface quality

- Heat treatment of metals (hardening, tempering , nitro-cementation) to impart hardness to the surface of metal parts. Qualitative hardening of the row materials mentioned increases the breaking load and wear resistance along with product properties.

|

|

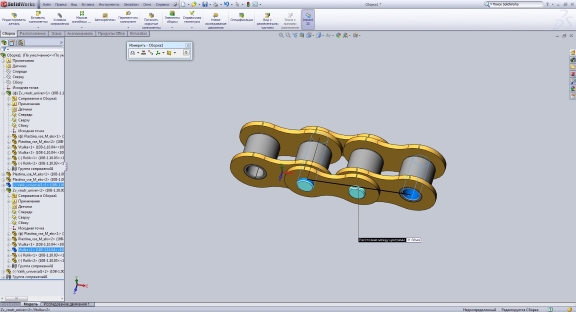

Chain assembling

|

- Assembling is performed on automatic equipment.

- After that follows chain stretching to reach the required elongation.

|

|

Acceptance tests

|

- To ensure the high quality the produced goods are tested on chain length accuracy, breaking load and serviceability of assembled parts.

|

|

Package, logistic and storage

|

- Finished goods are lubricated to ensure chain resistance to corrosion and different operating conditions.

- At customer`s request driving chains may be packed, for example, in plastic bags, corrugated boxes, on pallets, in wooden crates or in reels.

|